Essential Features to Look for in an Optical Fibre Diameter Analyser for Optimal Performance

Essential Features to Look for in an Optical Fibre Diameter Analyser for Optimal Performance

Blog Article

How an Optical Fibre Diameter Analyser Enhances Quality Assurance in Fibre Manufacturing

The integration of an Optical Fibre Diameter Analyser right into Fibre production processes stands for a substantial advancement in high quality control techniques. By providing real-time, exact dimensions of Fibre diameters, this technology attends to the essential need for consistency in production criteria.

Value of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is essential in the field of optical Fibre modern technology, as it straight affects the efficiency and dependability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying capacity, depletion, and overall transmission efficiency. Accuracy in gauging Fibre Diameter ensures that the optical residential or commercial properties are maintained within specified resistances, which is essential for optimal signal integrity.

Variants in Fibre Diameter can lead to raised losses as a result of scattering and modal dispersion, influencing the top quality of information transmission. In high-speed communication systems, such discrepancies can cause considerable degradation of signal top quality, bring about data errors and lowered performance. Furthermore, regular Fibre Diameter is crucial for compatibility with ports and splicing technologies, which are indispensable components of Fibre optic networks.

Quality assurance processes in Fibre production greatly count on exact Diameter dimensions to ensure conformity with industry requirements. By implementing durable measurement methods, manufacturers can improve item dependability, decrease waste, and improve total system performance. Therefore, the relevance of Fibre Diameter dimension can not be overstated, as it offers as a cornerstone in the improvement of optical Fibre technology and its applications in contemporary interaction networks.

How the Analyser Functions

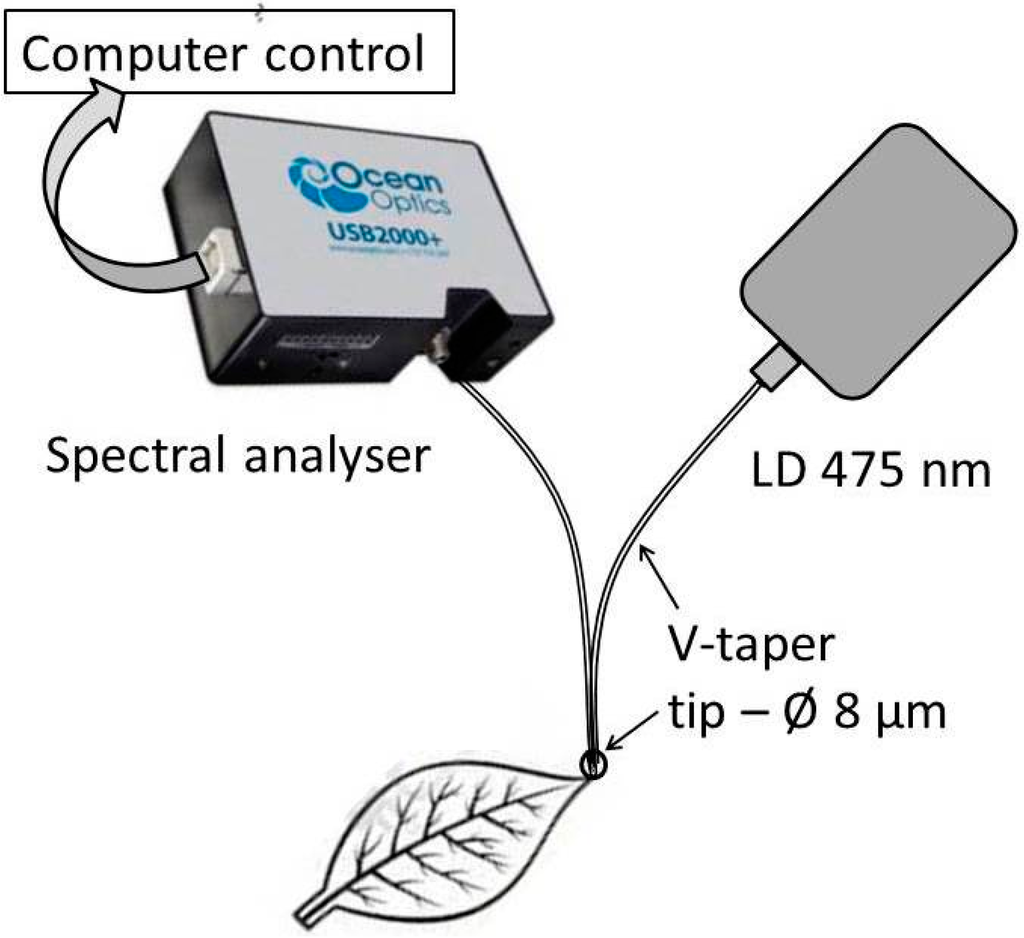

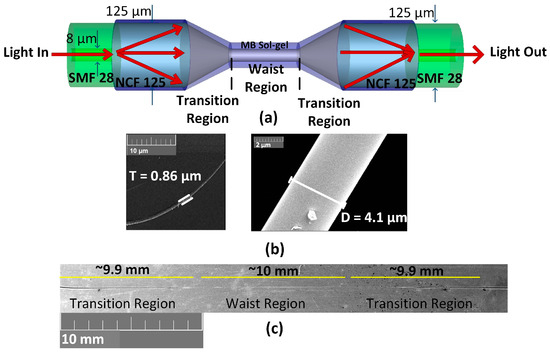

The reliable measurement of Fibre Diameter depends on advanced analytical strategies that ensure precision and integrity in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and advanced picture handling formulas to accurately evaluate the Diameter of fibers as they are generated

Initially, a laser beam is guided at the relocating Fibre, developing a cross-sectional darkness. The analyser captures this shadow utilizing high-resolution cams placed purposefully along the assembly line. The captured images are then processed in real-time to identify the Fibre's Diameter with outstanding precision.

The system makes use of innovative formulas that account for various factors, including variations in light intensity and environmental conditions, to enhance measurement reliability. It can detect minute changes in Diameter, such as changes that might take place during the manufacturing process.

Furthermore, the analyser can handling multiple fibers all at once, boosting throughput without jeopardizing accuracy. By providing rapid responses on the Diameter, the Optical Fibre Diameter Analyser plays a vital function in maintaining stringent quality assurance requirements, guaranteeing that the final item satisfies industry requirements and client requirements.

Advantages of Real-Time Tracking

While traditional approaches of monitoring Fibre Diameter usually include time-consuming post-production checks, real-time surveillance substantially enhances the performance and high quality of optical Fibre manufacturing. optical fibre diameter analyser. This positive approach permits producers to recognize discrepancies in Fibre Diameter as they take place, rather than waiting till production is total to assess high quality

By continuously determining the Diameter during manufacturing, manufacturers can make sure that the fibers meet rigorous her comment is here specifications, causing reduced variability and boosted consistency. Real-time tracking additionally enables instant rehabilitative actions to be taken, reducing waste and protecting against defective fibres from getting in the supply chain.

Furthermore, this innovation assists in boosted data collection and analysis, supplying understandings right into production trends and prospective locations for renovation. Such data-driven decision-making empowers manufacturers to enhance procedures and keep high criteria of quality control.

Additionally, real-time monitoring promotes a society of continual renovation within the manufacturing setting. Employees are more engaged when they can see the impact of their work in you could look here real-time, resulting in increased responsibility and a commitment to excellence. Generally, the application of real-time tracking systems in optical Fibre manufacturing equates to exceptional product high quality and enhanced client fulfillment.

Effect On Production Efficiency

Executing optical Fibre Diameter analysers dramatically boosts manufacturing effectiveness by improving the manufacturing process. These tools promote continual tracking of Fibre Diameter, permitting makers to discover discrepancies in real-time. By identifying inconsistencies without delay, assembly line can be changed rapidly, minimizing downtime and lowering the probability of creating defective items.

Moreover, the integration of these analysers right into the production workflow makes it possible for far better source allotment. With exact Diameter measurements, drivers can optimize product usage, making certain that resources are not thrown away on problematic fibers. This accuracy additionally adds to less revamp and scrap, inevitably reducing production expenses.

The automation provided by optical Fibre Diameter analysers minimizes dependence on hands-on inspections, which are commonly time-consuming and vulnerable to human mistake. Consequently, workers can concentrate on more critical tasks, improving total productivity.

In addition, the data produced from these analysers can educate procedure enhancements and promote better decision-making. By examining fads in Fibre Diameter variants, suppliers can execute positive actions to enhance production strategies and keep consistent high quality. In recap, optical Fibre Diameter analysers play a crucial function in enhancing production efficiency, causing greater top quality result and increased success.

Situation Researches and Success Stories

Throughout numerous sectors, study highlight the transformative effect of optical Fibre Diameter analysers on production procedures. One famous instance is a leading telecoms firm that encountered obstacles with irregular Fibre sizes, bring about raised denial prices. By incorporating an optical Fibre Diameter analyser, the business accomplished real-time tracking of Fibre dimensions, resulting in a 30% reduction in defects and significant cost financial savings.

In addition, a research study establishment focusing on innovative materials made use of optical Fibre Diameter analysers to refine their speculative processes. The analyser's ability to provide in-depth insights into Fibre consistency allowed the development of ingenious products with improved efficiency characteristics.

These success stories emphasize the important duty of optical Fibre Diameter analysers in boosting quality assurance, enhancing manufacturing efficiency, and driving advancement throughout diverse markets.

Verdict

Finally, the Optical Fibre Diameter Analyser plays a crucial role in improving top quality control within Fibre production. By offering exact, real-time dimensions and facilitating instant restorative activities, this technology considerably minimizes irregularity and minimizes waste. The implementation of such sophisticated tools promotes a society of continual renovation and functional performance, ultimately ensuring conformity with industry requirements and keeping competition. As optical fibre diameter analyser shown via various case research studies, the analyser shows necessary for attaining premium item top quality in Fibre production.

The execution of optical Fibre Diameter analysers permitted for strict top quality control, guaranteeing that the generated fibres fulfilled exacting industry requirements.In conclusion, the Optical Fibre Diameter Analyser plays a pivotal function in boosting quality control within Fibre manufacturing.

Report this page